Alps Alpine’s force sensor employs a piezoresistive method using Si semiconductor elements.

The load is detected using a piezoresistive element made by the MEMS process.

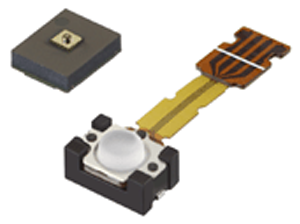

The new HSFPAR007A is the smallest in the industry*, and can be used with input devices such as stylus pens.

It can be used for a wide range of applications, such as adjusting the pressure balance of the robot arm grip.

*According to the manufacturer as of June 2020

Force sensor detection principle

The piezoresistive method is a detection method that uses the piezoresistive effect. When mechanical strain is applied to a semiconductor crystal (Si), the amount of electron movement changes due to a change in the internal energy structure, and the electrical resistance is reduced. It is a changing phenomenon.

As shown in the figure on the right, the electrical resistance changes depending on the direction of the strain applied to the piezoresistive element.

Piezo element Deformation direction and resistance

As shown below, when a load is applied causing the diaphragm to bend, the change in structure of the piezoresistive element alters the resistance.

In order to keep the size at a minimum, an analog output is used without the use of an integrated circuit.

Cross-section diagram of the sensor

Features of force sensor

Industry’s smallest size

Alps Alpine’s force sensor is the smallest in the industry to fit into the diameter of a small stylus pen.

(According to the manufacturer as of June 2020)

High linearity

The piezoresistive force sensor can achieve higher linearity vs other methods, but the Alps Alpine force sensor also has better linearity than other piezoresistive sensors.

Our HSFPAR004A/HSFPAR007A achieves 2% FS or less.Together, excellent hysteresis is evident.

* FS = Full Span (output fluctuation amount from 0 to 8N)

High sensitivity

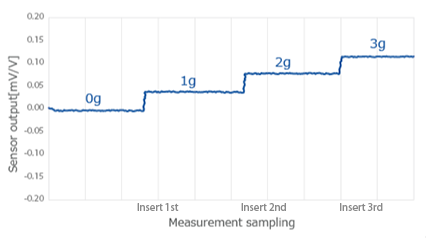

Alps Alpine’s force sensor can detect minute stress of 1g (≒ 0.01N) level.

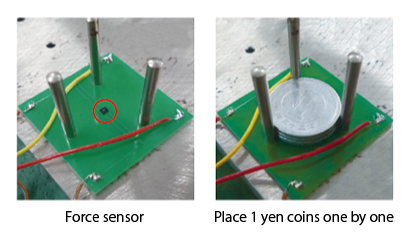

Experimental example

In an experiment in which a 1-yen coin (1 g) is superimposed on a force sensor, it can be reliably detected as shown in the graph.*

As mentioned above, the Alps Alpine force sensor has a high degree of linearity, so this can be achieved over the entire load range.

*Signal amplification processing such as operational amplifiers and signal stabilization processing such as averaging are required to detect minute stress.

With this kind of performance, the stylus pen pressure can be easily detected and provide a comfortable writing experience in terms of brush smoothness and reproducibility.

In addition, since it can be detected from minimal stress at the zero stroke level (0.01N), it can be used for industrial equipment that handles precision machinery.

High reliability

Guaranteed operating life of one million uses within the working load range (up to 8N).

In addition, the newest product HSFPAR004A/HSFPAR007A has a maximum rated load of 30 to 40% higher than conventional products, and can withstand loads of up to 55N.

HSFPAR303A, a module (FPC mounting type) that can withstand up to 200N is also available.

Application example

Adjustment of pressure balance in

robot arm grip

Mounted on the sole of a biped robot to

detect load and adjust balance

Pen pressure detection of various input

devices, such as stylus pens

Lineup

| Product number | Product pictures | Size | Features | Operating load range | Power-supply voltage | Maximum rated load |

|---|---|---|---|---|---|---|

|

HSFPAR003A |

|

2.0 × 1.6 × 0.66mm | Maximum rated load | 0 ~ 8N | 1.5 ~ 3.6V | 40N |

|

NEW HSFPAR004A Buy Here |

|

2.0 × 1.6 × 0.66mm | Maximum rated load | 0 ~ 8N | 1.5 ~ 3.6V | 55N |

|

NEW HSFPAR007A Buy Here |

|

1.5 × 0.85 × 0.68mm | Maximum rated load | 0 ~ 8N | 1.5 ~ 3.6V | 55N |

|

HSFPAR303A Buy Here |

|

4.0 × 2.7 × 2.06mm | Shock resistant unit type | 0 ~ 7N | 1.5 ~ 3.6V | 200N |