~Maker Interview~

A place for people to talk to those in charge of development and product planning regarding strategies

and future policies, focusing on manufacturer HOT topics and current most focused products.

※Delivering the latest industry trends every month.

The source of our competitiveness is the abundant lineup of spring fingers that are indispensable for electronic devices.

Kelvin Hsieh

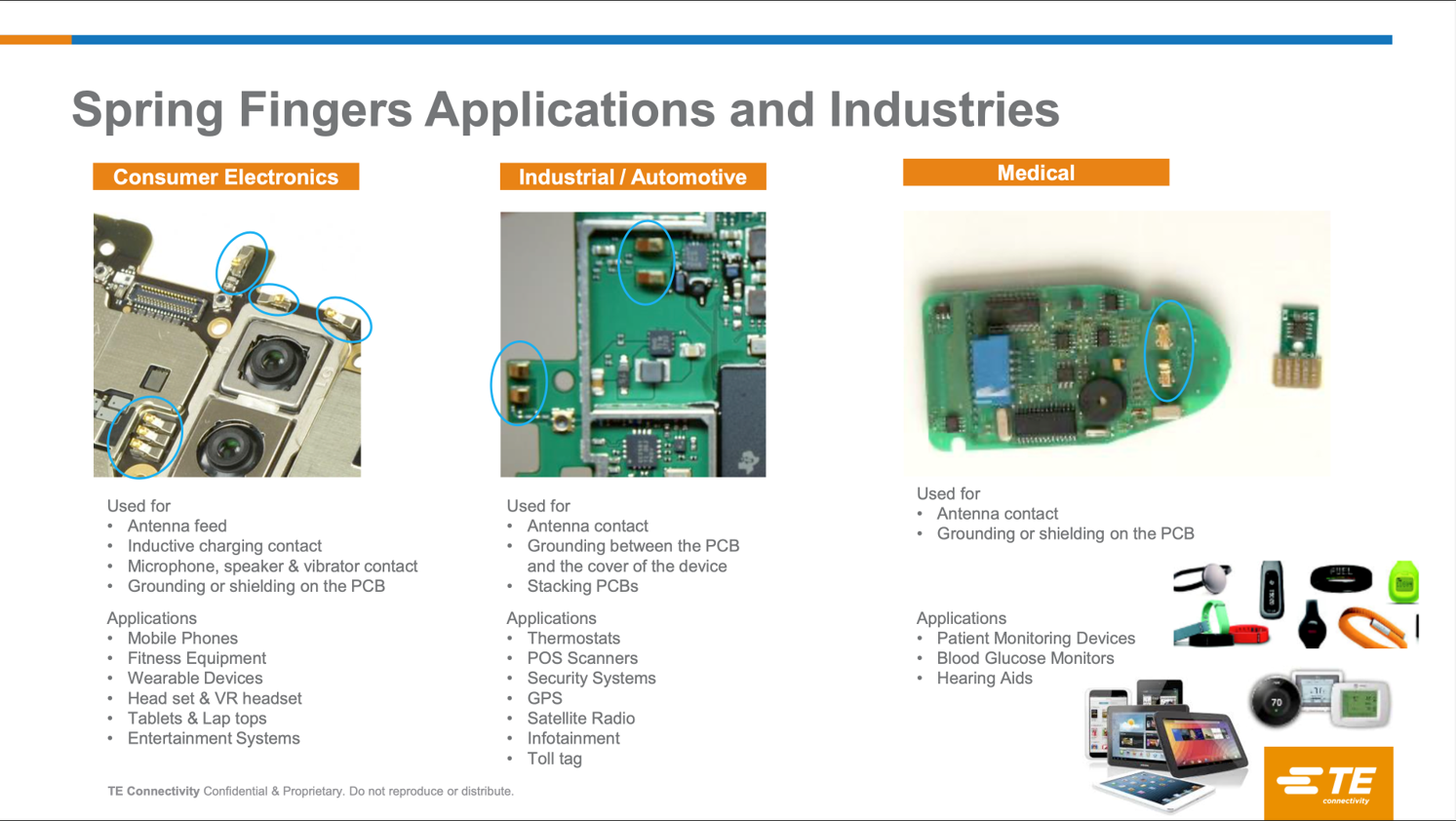

Spring fingers are used in a wide range of applications, from portable electronic devices such as smartphones and smart watches to in-vehicle equipment and industrial equipment. Although it is an extremely small mechanical component, it plays an important role inside various electronic devices. Typically it is used for the connection for signal or power, grounding on PCB to eliminate EMI noise, and antenna feeding to PCBA.

TE Connectivity is in a leading position in the global market for spring fingers. Originally, the company's spring fingers were developed and designed in Japan, and have excellent characteristics and high reliability. So this time, we asked Mr. Kelvin Hsieh, the product manager for spring finger, about the company's product application, product line, and product features.

(Interviewer: Katsumi Yamashita = technology journalist)

Spring finger isn't a word you're all too familiar with. What other names are there?

Hsieh Spring finger is the most popular name to describe this mechanical component. However, there are other names for it. Examples include grounding contacts, grounding springs, spring contacts, and PCB contacts.

I would like to know how to use the spring fingers specifically.

Figure 1: Application example of spring fingers

Examples of adoption include consumer equipment, industrial / in-vehicle equipment, and medical equipment. They are used for antenna feeding, grounding for PCBA, and signal/power transmission.

Hsieh The spring fingers themselves are used by soldering. The spring finger has a "spring" function, and if you apply force from above and press it, the height will shrink. This principle is used to form reliable electrical connections (Fig. 1). For example, if you have a small antenna, you can easily connect the feed point by pressing it against the spring finger. If you use a wire or the like to connect, you have to solder, but using spring fingers eliminates that. Save time and effort. Moreover, since it is just a matter of pressing and connecting, it also has the effect of saving space.

How do you use spring fingers for PCB grounding and shielding?

Hsieh Recently, such cases have become rare, but 10 or 20 spring fingers are arranged around the periphery of a small printed circuit board built into a mobile phone, and the housing (case) that plays the role of ground is pressed against it creating a ground connection. A shielding effect can also be obtained, reducing radiated electromagnetic noise (EMI).

What kind of electronic devices are spring fingers used in? I would like to know about your record.

Hsieh For example, US-based Fitbit and US-based Garmin use it in wearable devices, US-based Motorola Solutions in wireless communication devices, and Denmark’s GN Audio (brand name Jabra) has a track record of being used in headsets. Based on this story, you might think that spring finger can only be used in electronic devices that are more like wearables. But that is not the case. There are many examples of adoption other than wearable terminals. Specifically, Square in the US uses it for POS terminals, Bosch in Germany for heating systems, and Fleet Complete in Canada for smart transportation systems. No industry is selected. In fact, it is used for various purposes. The field of application of spring fingers is extremely wide.

Selecting the optimal spring finger by identifying four product specifications

Could you introduce how to select appropriate spring finger?

Figure 2: The four specifications of the spring finger

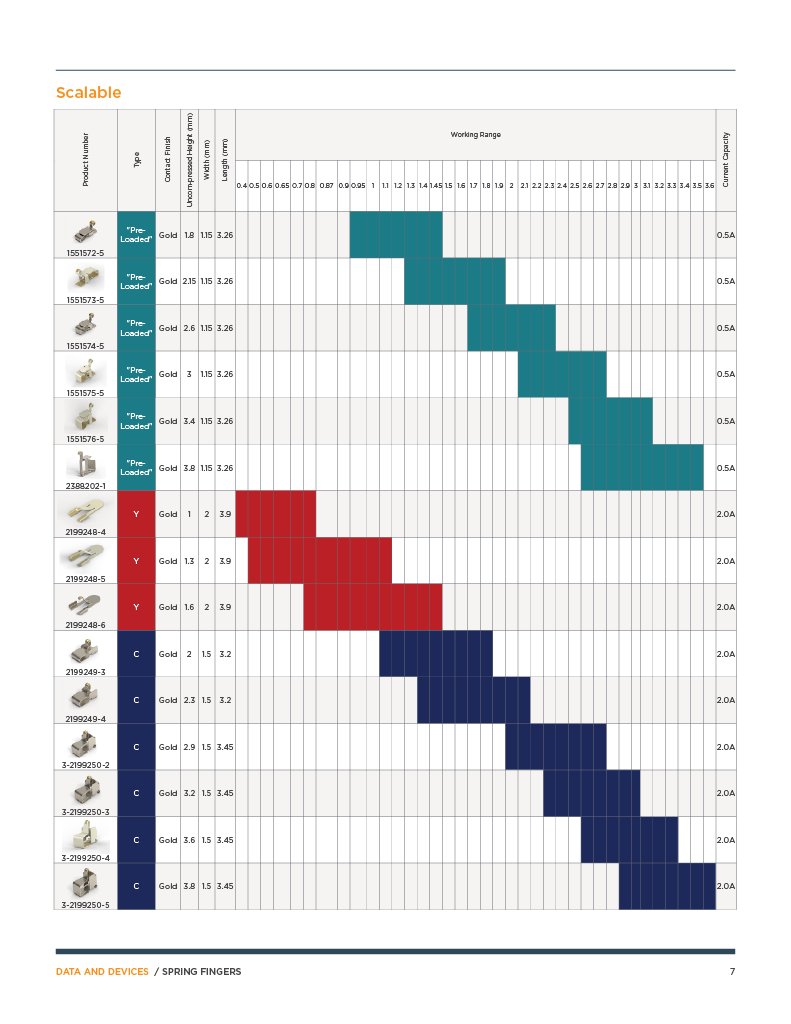

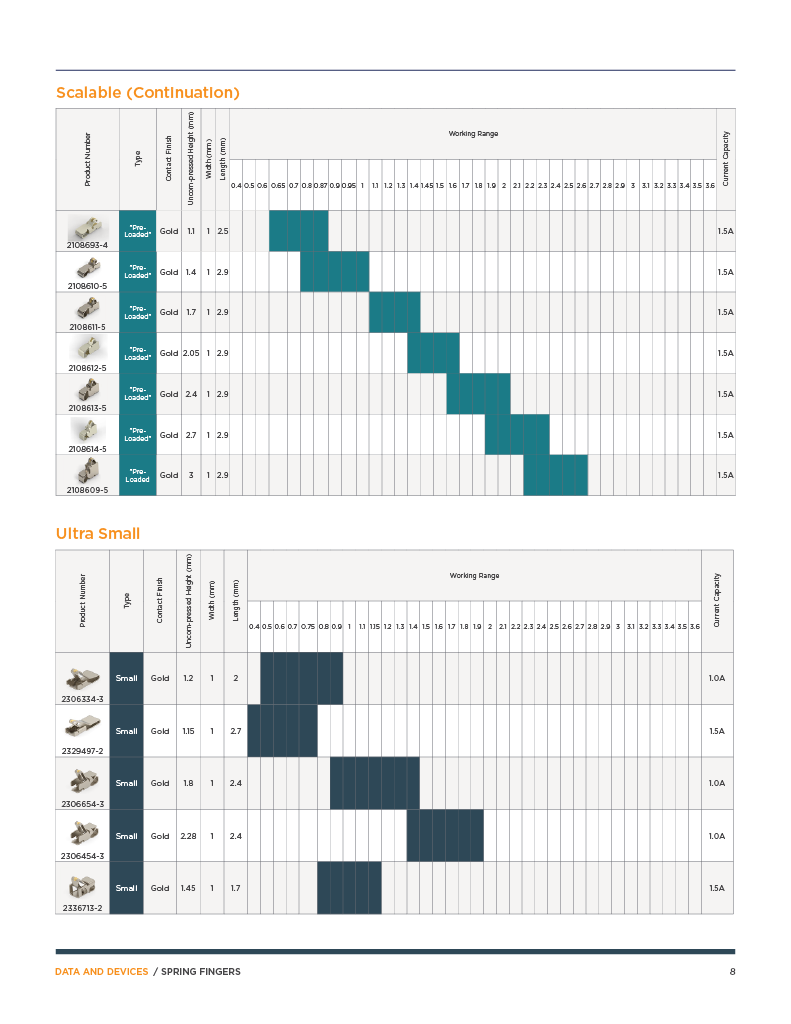

Products are selected according to four specifications: "product type", "uncompressed height", "working range" and "current capacity".

Hsieh In short, there are 4 specifications, which are “product type”, “uncompressed height”, “working range(working height)”, and “current capacity”.(Fig. 2) These four are critical spec.

With knowing these 4 spec., you will be easy to find the best spring finger for your design.

What is the four axis? Please elaborate on each.

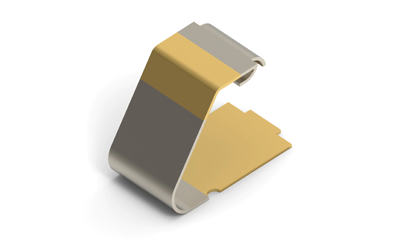

Hsieh Product type refers to shape and structure. Specifically, there are five types: "C type", "Box type", "Y type", "Pre-loaded type", and "Ultra-small type" (Figures 3 and 4).

Uncompressed Height is the original height when no force is applied to the printed circuit board. We have products from 0.8 to 7.0 mm. "Working range" is the distance (height) that shrinks when it is actually applied to an electronic device and pressed against a printed circuit board to apply force. Naturally, the number is smaller than the uncompressed height (Uncompressed Height). The final "Current Capacity" is the maximum amount of current that can flow through the spring fingers.

Please tell us more about the five product types.

Fig.5: Pre-loaded type

It is a pre-loaded type spring finger. Since a constant load is applied in advance, the relationship between the pressing force and the shrinking distance (height) is constant within the operating range. Even a weak force can be pressed and contact can be formed.

Hsieh The "C type" and "Box type" have a standard and simple shape and are characterized by being easily applicable to various purposes. The “Y type” also has a simple shape, but low in height, and ideal for applications that require low profile.

"Pre-loaded type" is a type with special characteristics (Fig. 5). As the word Pre-loaded suggests, it is in a state where a certain amount of load has been applied in advance. Therefore, the relationship between the pressing force and the shrinking distance (height) is constant within the operating range. All of the C type, Box type, and Y type cannot gain the distance (height) to shrink unless they are pressed strongly. If you use the pre-loaded type, you can get by with 0.2N where 0.5N is normally required to maintain a certain height. In other words, a force of 0.3N is no longer required, and a stable contact can be secured with a weak force. User evaluation and sales for the Pre-loaded type is high, and in fact, some users (electronic device manufacturers) only use the Pre-loaded type.

The last "Ultra-small type" is also a preloaded type. However, the external dimensions are relatively small compared to the pre-loaded type. Therefore, it is classified into another type called Ultra-small type.

Reduced pressing force with preload

Why do you need preload? Please explain in a little more detail.

Hsieh For example, thin printed circuit boards and antennas are delicate and cannot be pressed with a strong force. We received feedback from customers that they wanted a device that would allow them to attach with a weak force. The Pre-loaded type responds to that feedback.

What happens if you don't adopt the Pre-loaded type?

Hsieh There are cases where only one spring finger is used, and there are cases where 10 or 20 are used at the same time. Using so many spring fingers puts a lot of stress on the printed circuit board. As a result, there is a danger of deforming or warping the printed circuit board. Pre-loaded type is used to prevent such a situation.

What is the difference between Ultra-small type and Pre-loaded type? I would like to know the definition of that.

Hsieh The Ultra-small type has been on sale for several years, but was re-released in April 2022. We are currently working with sales agents to strengthen sales promotion activities. The Ultra-small type gets its name when it meets two conditions. One of the two conditions is that the width of the footprint is 1mm. The other one has a low Uncompressed Height. Spring fingers that meet these two conditions are classified as Ultra-small type. Please understand that it is a product that pursues further miniaturization. However, please note that there are some exceptions.

What kind of electronic equipment is the ultra-small type used in?

Hsieh This type is often used in smaller electronic devices, although its use is by no means limited. Examples include e-cigarettes, smartwatches, and TWS (True Wireless Stereo) earphones.

Product portfolio and technical capabilities are strengths

Where are the competitors in Japan?

Hsieh There are several competitors in Japan.

What are your strengths compared to your competitors' products?

Hsieh Our strength lies in our wide product portfolio, advanced technology, and high quality. For example, the plating thickness can be customized according to the user's purchase quantity. In addition, customers can expect reliability and a high level of technical capabilities supported by the fact that it has already been sold to a large number of users around the world.

Who is the world's number one manufacturer in the spring finger market?

Hsieh Depending on the target market field, the manufacturer with the world's top share will differ. For this reason, it is difficult to declare the manufacturer with the world's top share for the entire market.

However, it can be said that our company is at least in a very strong position in the consumer device and IoT device market fields. In fact, we have a track record of shipping several million units per month to specific users.

Spring finger was in charge by Japan engineering team. But it is transfer to China engineering team. TE Japan still have Japan quality ppl in Japan, they still will get involved if there is quality issue. You can check with our sales.

As for technical issue currently it is in charge by China engineering team.

Product portfolio and technical capabilities are strengths

Hsieh TE is one of the earliest manufacturers enter this market.

Sufficient development of distribution networks is the key to expanding sales worldwide. In this regard, we have established a broad distribution network, so that we are able to sell to various electronic equipment manufacturers around the world with the help of sales agents.

Product Line

The SPRING FINGER introduced in this article is now on sale at Chip One Stop!